Welcome To Nixin Trading

Focus On Mobile Conveyors Production ManuFacture

The company has strong technical strength and an experienced and professional R&D team that constantly studies and innovates and actively introduces advanced technologies and concepts

High Quality

Use time to accumulate trust and define standards with quality

Good Price

Affordable price without sacrificing quality

Exceptional Service

From consultation to after-sales, we define high standards with professionalism

Fast Delivery

Every on-time delivery is our fulfillment of our promise

Our Prodcuts

Focusing on the research and development of mobile conveyors

Who We Are

Your Trusted Partner In Material Handling

Hengshui Nixin Trading Co., Ltd. is a foreign trade company focusing on the research and development, production and export of mobile conveyors, and is committed to providing efficient and reliable material transportation solutions to global customers.

Professional Expert

Solve material transportation problems for you

Reliable Quality

Buy with confidence and worry-free quality

Years Of Experience

- Cutting-Edge Expertise

- Overall Material Handling Solution

- Client-Centric Collaboration

Over 10 Years Manufacturer Of Industrial Conveyor Belts

Our Vision

The global leader in intelligent material handling

Our Corporate Culture

We forge products with strict standards and strive for “zero defect” delivery.

Our Mission

Deeply understand customer needs and provide service experience that exceeds expectations.

Why Choose Us

Choose Nixin Trading To Help You Solve Problems

Hengshui Nixin Trading Co., Ltd. exports mobile conveyors globally, partners with renowned companies, and upholds “Quality First, Customer First” principles with reliable products and services, striving to enhance quality and create shared value worldwide.

Extended Equipment Lifespan

Intelligently protect the mechanical heart, making every second run longer

Improved Safety Standards

Through stress testing, safety can withstand extreme verification

Enhanced Customer Satisfaction

Not just delivering machines, but also being a partner throughout the entire process

Application Cases

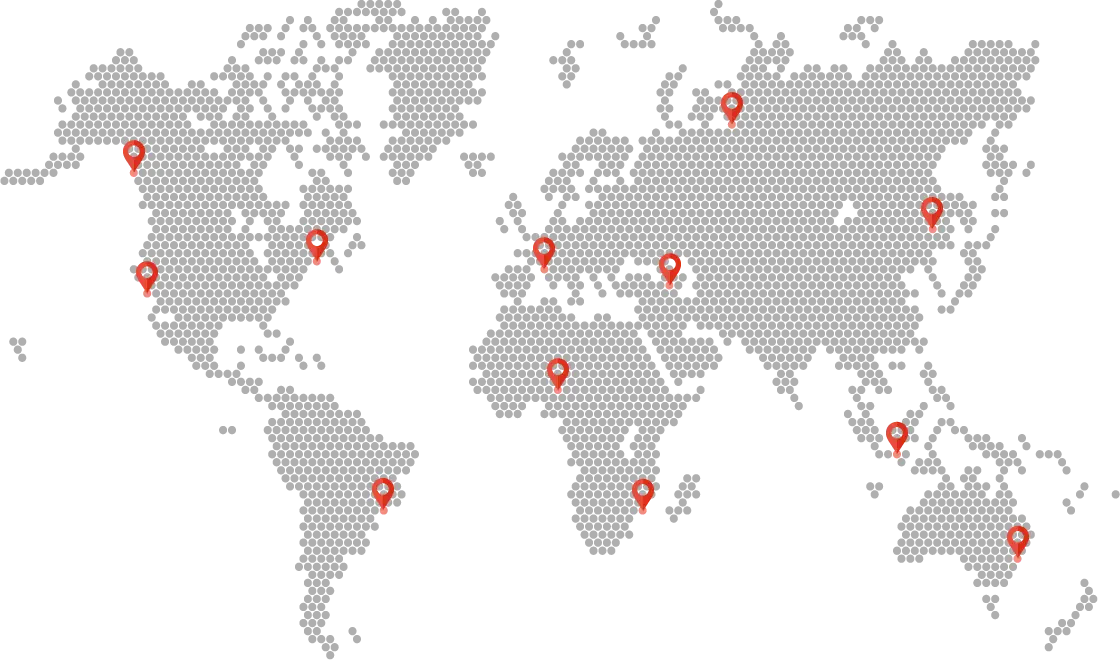

Our products have been exported to many countries in the global market

Mining Industry

Transport mineral materials to designated locations quickly and accurately

Port Industry

Able to quickly and accurately complete cargo loading, unloading and transportation tasks

Logistics Industry

Able to efficiently complete the tasks of sorting, loading, unloading and transporting goods

Construction Industry

Able to transport materials at different construction locations

Agriculture

Can be used for loading and storage of grain and feed

Food Processing Industry

Use time to accumulate trust and define standards with quality

Trusted By Multiple Client Companies

The company has strong technical strength and an experienced and professional R&D team that continuously researches and innovates, and actively introduces advanced technologies and concepts. With an accurate grasp of market trends and a deep understanding of customer needs, the company continues to optimize product design and improve product performance.

Testimonial

Client Feedback & Reviews

Need More Help

Solve Product-Related Problems For You

Send Us A Message

Solve For You

Most Popular Questions

Rapidly customize solutions based on customer needs

Chain type (carrying capacity of more than 10 tons) is preferred for heavy-load materials, belt type (speed 0.5~2m/s) is optional for light/medium loads, roller type is preferred for high-speed short-distance conveying, and hanging type is suitable for high altitude/narrow space; special occasions require customized wear-resistant/corrosion-resistant/explosion-proof versions based on temperature, humidity, and dust level

Use a laser level to calibrate the track benchmark and adjust the length of the boom to center the conveyor belt; replace worn rubber-coated rollers (wear-resistant layer thickness ≥ 8mm), and install anti-deflection rollers at key points; tighten all bolts and apply molybdenum disulfide grease regularly to prevent rust

Clean the chain track and add high-temperature resistant grease (NLGI grade 2); check the grid voltage stability and install an overload protection relay (the action value is set to 120% of the rated current).

Solutions include adjusting the lead time, reinforcing the platform, ensuring uniform incoming materials, calibrating sensors, checking the solenoid valve cylinder, removing external forces, and considering the weight of the packaging bag. Environmental factors (such as high temperature, low temperature, humidity, vibration, dust, and static electricity) may also require protection and selection of appropriate sensors. In addition, aging, wear, improper installation, and incorrect parameter settings of equipment components can also affect the process. Regular maintenance, correct installation, and reasonable parameter settings are required. If the problem persists, contact the manufacturer's after-sales service.